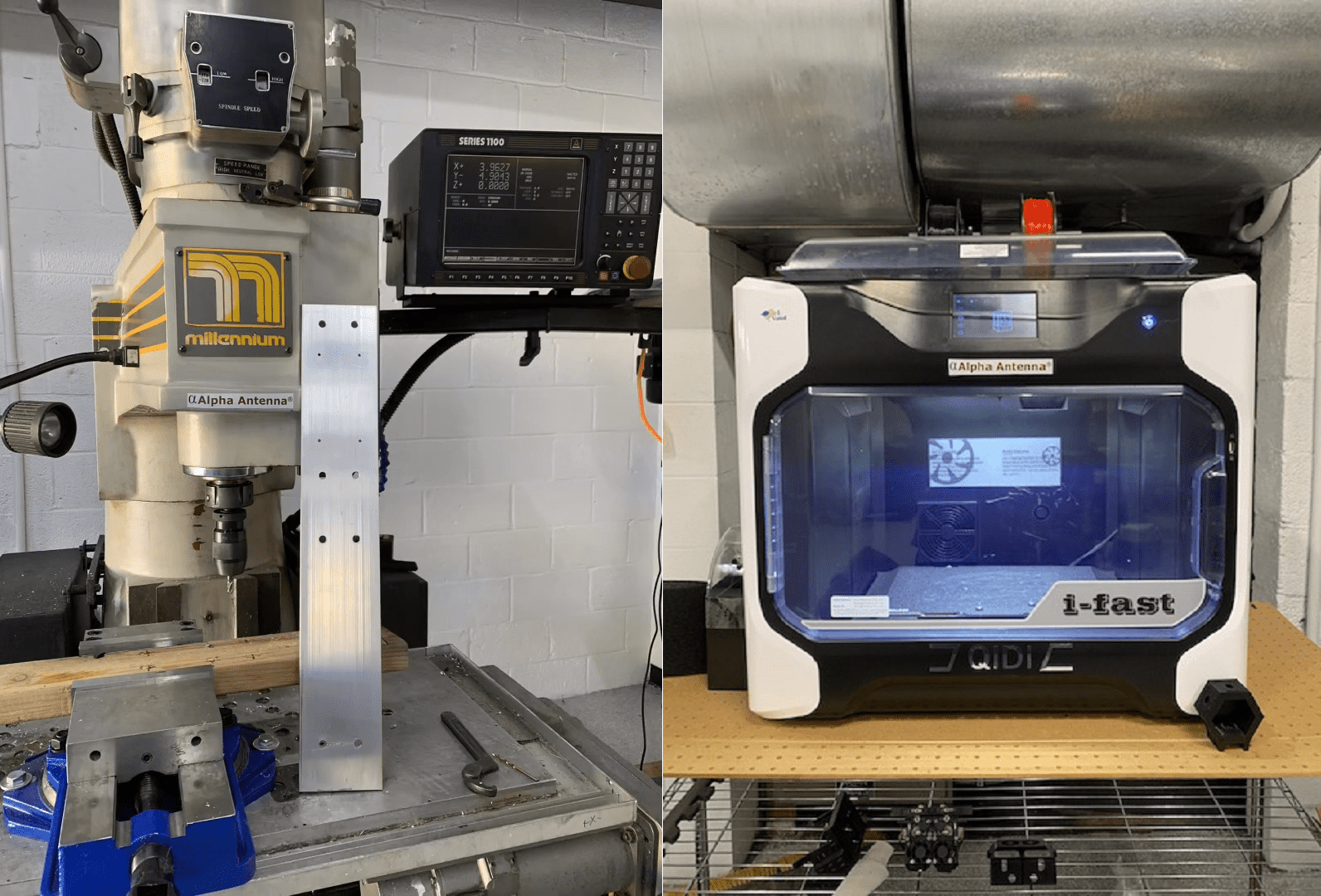

The success story of CNC and 3D machine deployment at Alpha Antenna was a journey that took a long time to complete. Today our CNC and other 3D machines are in production creating components with great accuracy, some down to 1 thousandth of an inch.

Many years ago, it started with finding a moving company that could provide interstate transport for CNC and other such machines. Once we found a reputable mover, we had them placing machines into our facilities for some time now. During those processes, we also had a local electrician install dedicated wiring for each machine, some even to dedicated 220VAC Single Phase breakers.

I remember when we powered our first CNC machine on and recall that the computer, which drives the CNC Machine, had lost its’ BIOS setting in CMOS RAM during transport. It was a long process starting from scratch to reprogram the PC’s BIOS so that it would communicate with its’ CNC machine. I reflect on the challenge of determining the correct settings yet again after they were lost when power was removed from the PC.

Please understand that CMOS RAM is sustained by a rechargeable battery, which had failed. That battery was soldered directly onto the motherboard, which we replaced. Then we went through the process of programming the BIOS once again from scratch. This time we took pictures of each page for the BIOS settings from the computer’s screen.

After several months, our first CNC machine was finally ready! During that time, we had taught ourselves about speed/feed formulas for the various metals and tooling we would use. Then we developed the designs that would create our first production item using Fusion 360. As if that wasn’t fun enough, we also created production items directly through the machine’s “Teach” feature.

Back in the day we needed to find the machines ZERO, after which time we realized why some do not turn their machines off. We decided to ALWAYS return to Zero before turning the machine off. That’s hugely important! Fortunately, and with advancements, that fun exercise has become more automated.

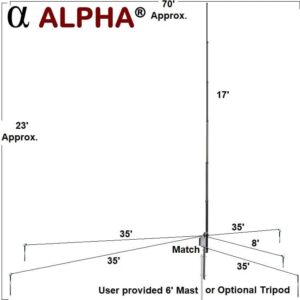

We can now state that we are experienced and in full production of such items as the Base Mounting Plate for our 10-80 Meter Vertical HF ProMaster Antenna and so much more that our reliance on outside sources has been nearly eliminated.

After such a long and rewarding journey, I was reminded again to “Never Give Up!”

Steven, Founder – Alpha Antenna

-

Base HF EmComm AntennaCall for PriceRated 5.00 out of 5 based on 27 customer ratings

Base HF EmComm AntennaCall for PriceRated 5.00 out of 5 based on 27 customer ratings -

HF Base HD Antenna$750.00Rated 4.97 out of 5 based on 30 customer ratings

HF Base HD Antenna$750.00Rated 4.97 out of 5 based on 30 customer ratings